“Thirty different beers based on a fan base is a unique thing.”

The post Buffalo Pils Scores a Touchdown appeared first on CraftBeer.com.

“Thirty different beers based on a fan base is a unique thing.”

The post Buffalo Pils Scores a Touchdown appeared first on CraftBeer.com.

“Thirty different beers based on a fan base is a unique thing.”

The post Buffalo Pils Scores a Touchdown appeared first on CraftBeer.com.

“Thirty different beers based on a fan base is a unique thing.”

The post Buffalo Pils Scores a Touchdown appeared first on CraftBeer.com.

“Thirty different beers based on a fan base is a unique thing.”

The post Buffalo Pils Scores a Touchdown appeared first on CraftBeer.com.

“Thirty different beers based on a fan base is a unique thing.”

The post Buffalo Pils Scores a Touchdown appeared first on CraftBeer.com.

“Thirty different beers based on a fan base is a unique thing.”

The post Buffalo Pils Scores a Touchdown appeared first on CraftBeer.com.

“Thirty different beers based on a fan base is a unique thing.”

The post Buffalo Pils Scores a Touchdown appeared first on CraftBeer.com.

“Thirty different beers based on a fan base is a unique thing.”

The post Buffalo Pils Scores a Touchdown appeared first on CraftBeer.com.

“Thirty different beers based on a fan base is a unique thing.”

The post Buffalo Pils Scores a Touchdown appeared first on CraftBeer.com.

“Thirty different beers based on a fan base is a unique thing.”

The post Buffalo Pils Scores a Touchdown appeared first on CraftBeer.com.

“Thirty different beers based on a fan base is a unique thing.”

The post Buffalo Pils Scores a Touchdown appeared first on CraftBeer.com.

“Thirty different beers based on a fan base is a unique thing.”

The post Buffalo Pils Scores a Touchdown appeared first on CraftBeer.com.

“Thirty different beers based on a fan base is a unique thing.”

The post Buffalo Pils Scores a Touchdown appeared first on CraftBeer.com.

John Palmer guides you through brewing this delightful beer, that is widely praised but far too often poorly replicated.

John Palmer guides you through brewing this delightful beer, that is widely praised but far too often poorly replicated.  John Palmer guides you through brewing this delightful beer, that is widely praised but far too often poorly replicated.

John Palmer guides you through brewing this delightful beer, that is widely praised but far too often poorly replicated.  Alice Springs Brewing Co is taking its first step outside the NT with the acquisition of SA's Beer Garden Brewing.

Alice Springs Brewing Co is taking its first step outside the NT with the acquisition of SA's Beer Garden Brewing. Don't call it a comeback: Detroit's vibrant craft beer scene mirrors the city's own renaissance.

The post Celebrating Detroit’s Craft Beer History appeared first on CraftBeer.com.

The former Brews News editor will share insights from more than a decade in beer media at a session on 15 October at Melbourne’s Local Taphouse.

The former Brews News editor will share insights from more than a decade in beer media at a session on 15 October at Melbourne’s Local Taphouse.  From industrial chemistry to marketing to brewing, Esker Beer Co’s Charlie Claridge leans on his diverse experience to create award-winning beer.

From industrial chemistry to marketing to brewing, Esker Beer Co’s Charlie Claridge leans on his diverse experience to create award-winning beer.  Slated to open in November, the new venue will be Mountain Culture's first inner-city joint, housing the brewery's new barrel program.

Slated to open in November, the new venue will be Mountain Culture's first inner-city joint, housing the brewery's new barrel program. Ice cream soda floated into our collective consciousness 150 years ago. Now, a beery take on this fanciful beverage is winning converts.

The post A Dreamy Pairing: Beer & Ice Cream appeared first on CraftBeer.com.

BeerFest Australia engages more than 30 musical acts over its festivals, with Sneaky Sound System headlining the Sydney event.

BeerFest Australia engages more than 30 musical acts over its festivals, with Sneaky Sound System headlining the Sydney event.  Beer & Brewer has partnered with Sydney Beer Week to present the 2024 Beer & Brewer Awards at a live ceremony on 20 October.

Beer & Brewer has partnered with Sydney Beer Week to present the 2024 Beer & Brewer Awards at a live ceremony on 20 October.  Now encompassing 18 independent breweries across six suburbs, the Inner West Ale Trail has received funding to boost its status as the craft capital of Australia.

Now encompassing 18 independent breweries across six suburbs, the Inner West Ale Trail has received funding to boost its status as the craft capital of Australia.  Owner Ralph Bungard spoke about the changing perception of beer, 20 years of ups and downs, and what makes Three Boys special.

Owner Ralph Bungard spoke about the changing perception of beer, 20 years of ups and downs, and what makes Three Boys special. The fourth-largest producer of hops in the U.S., Michigan has become a unique test subject for the future of American hop production—and craft beer itself.

The post The New Nobles: Michigan Hops appeared first on CraftBeer.com.

New Zealnd's Te Aro Brewing, has been ordered to remove one of its beers from sale after it was found to be in breach of advertising standards.

New Zealnd's Te Aro Brewing, has been ordered to remove one of its beers from sale after it was found to be in breach of advertising standards.  Frenchies Brewery Head Brewer Sam McDonough spoke to Beer & Brewer about his decade in the industry, working with some of Australia’s most well-known craft breweries.

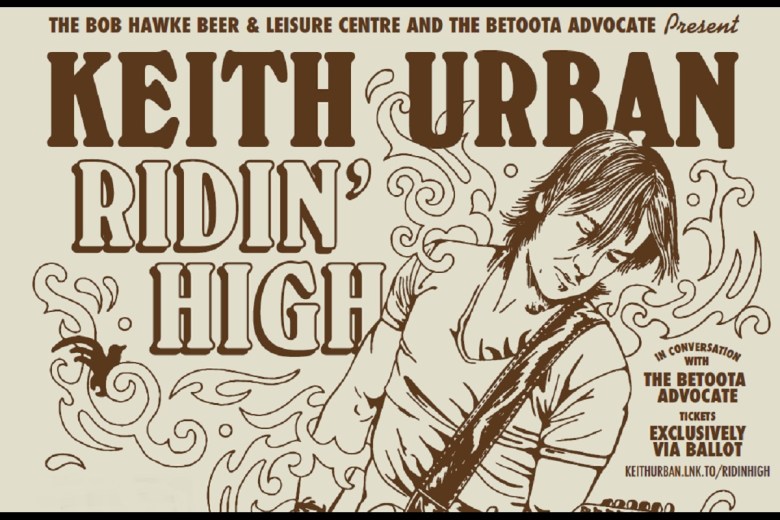

Frenchies Brewery Head Brewer Sam McDonough spoke to Beer & Brewer about his decade in the industry, working with some of Australia’s most well-known craft breweries.  To celebrate the release of his new album Keith Urban is having a night of music and conversation in Marrickville in September.

To celebrate the release of his new album Keith Urban is having a night of music and conversation in Marrickville in September.