American breweries are embracing Czech pouring traditions to elevate foam quality, flavor, and the overall craft beer experience.

The post Czech Your Taps: Breweries Level Up with Perfect Pours appeared first on CraftBeer.com.

American breweries are embracing Czech pouring traditions to elevate foam quality, flavor, and the overall craft beer experience.

The post Czech Your Taps: Breweries Level Up with Perfect Pours appeared first on CraftBeer.com.

(Detroit, MI) – Get ready, Detroit. Pączki Beer returns for 2025, and this year, we’ve listened to what you’ve been asking for: Raspberry is back! Everyone asked for Raspberry Pączki last year, so we brought it back with extra vanilla cream and the fruit-forward flavor that always sells out. But we didn’t stop there. For […]

The post Eastern Market Brewing Co. Unveils 2025 Pączki Beer Lineup appeared first on The Full Pint - Craft Beer News.

While women are currently a minority in the homebrewing community, they are increasingly taking on leadership roles and becoming the most outspoken proponents of the hobby.

The post Can Women Save Homebrewing? appeared first on CraftBeer.com.

I used to do a talk titled "Embracing Homebrewing" (here it is on the Beersmith Podcast). Basically, rather than worry about replicating the exact process/results of a craft brewery, enjoy the things that you can do on a small scale without regulatory oversight (dosing in spirits, ice distillation, foraging) or economic pressures (expensive ingredients, not worrying about extract efficiency) etc.

The more great brewers I talk to... the more I realize that Scott and I run Sapwood Cellars like a big homebrewing operation more than a small craft brewery. We're lucky that we have enough support and direct sales that don't have to worry too much about cost, time, or efficiency. This post dives into that a little deeper on the benefits of inefficiency using the six beers included in the upcoming shipment of our Out-of-State Shipping Club as examples!

Variability: Flemish Gothic

Most mixed-ferm breweries have a single house culture they pull off a tank or set of barrels or a specific commercial microbe blend that they add to every batch of a given beer. It makes a lot of sense, it promotes consistency and you don't have to worry about blending/attenuation. However, for me it lacks the dynamic flavor options and variety in finished beers I love. Every time we brew a new sour base beer, we select a barrel with a culture that suits it, and add some to primary (along with a healthy Saccharomyces pitch).

Flemish Gothic is a beer we blended from three different wine barrels, with three different base sour reds (Standard Red, Provisional Strength, Vin De Céréale) each with a different culture. That allowed us to dial in the acidity, malt balance, and level of Brett expression. It worked out that we did a three-year blend rather than the standard old/young blend done by Rodenbach and many other Flemish Reds.

Flemish Gothic Tasting Notes

Smell - Real range, right from the start. Honey, leather, blackberry fruit leather, some dried hay of hops. Cocoa, Tootsie Pop. I could see Balsamic, but without the vinegar or nail polish.

Appearance - Beautiful ruby red. Good clarity. Stable off-white foam, pours three fingers.

Taste - Bright lactic acidity, with dried cherries in the finish. No acetic harshness in the finish. Mild perceived fruity sweetness. A little damp oak, but not aggressively woody despite the extended aging thanks to the well used barrels. Could have even used a little more. Slight licorice as it warms.

Mouthfeel - Medium body, pretty smooth. Firm carbonation. Slightly oaky astringency.

Drinkability - Really good, lots of malt/barrel/Brett character all working together without excessive acidity. One of my favorite sours we’ve done, right up there with Growth Rings. I’d like to blend something similar again in a few years.

Changes for Next Time - A few people suggested more acidity, but I like it as is. It’s considerably more acidic than my recollection of Flemish Kiss from Commons. I’ll be looking forward to seeing how this one ages.

Effort: Gindicators 2024

Local in-season fruit is less expensive than buying IQF or Puree. What you are paying for with those is convenience and consistency. Buying locally requires figuring out who grows good produce, building relationships, and being on top of communication. For Gindicators, we sourced peaches, nectarines, and apricots as the summer progressed. I picked through them each day, processing and freezing the fruit that was ripe. Waiting on the rest. It's worth it for me to go that extra length to create the best stone fruit aroma possible!

We paired that with a low-acidity (higher hoping rate) pale base aged in gin barrels. Stone fruit in general and apricots in particular bring a lot of their own acidity. After refermentation we blended in a 30 gallon "double gin-barrel-finished" higher-acid beer to add more gin character.

Gindicators 2024 Tasting Notes

Smell - Funky nose, damp hay Brett. As a result, it reads more saison-ish than our sours usually do. Melds in a fun way with citrus and rosemary notes from the barrels. Plenty of stone fruit, yellow peach especially, but leaves room for the other aromatics. Pez candy. Overall vibrant and varied.

Appearance - Mild haze, bright yellow body. Sticky white head, good density. End of the bottle pour has some small yeast floaties. Seems like more yeast adhered in the bottle than usual too. Maybe the 58W3 from refermentaiton?

Taste - Snappy acidity (malic?), glad we selected lower acid barrels for this one! Tastes more acidic than the >3.5 pH suggests. Lots of fresh apricot and nectarine on the palate. Minimal sweetness. Juniper comes through in the finish, piney, Sprite-like. Faint bitterness from the higher IBU component in the blend.

Mouthfeel - Firm carbonation. Light body, but not tannic or harsh despite the extended aging.

Drinkability - The acid level is just about right for my tastes, lingers for a second, but then goes.

Changes for Next Time - Not much to change on this one. I could be tempted to go up 25% on the fruit, it had a little more punch before we blended in the last 30 gallon gin barrel. Likely wasn’t necessary to repitch yeast so soon after refermentation on the fruit?

Process: Neologism 2024

We treat our sour beers with the same care and attention to sanitation and oxygen ingress as we do our Hazy IPAs. We purge the barrels and bottles with CO2, we fill the blending tank with water and push it out to remove all of the oxygen before transers. I think it really shows with the "vibrancy" of the aromatics we are able to achieve, especially in a dry hopped sour like Neologism. It goes into the blending tank on hops, and infuses cold for 48 hours before bottling. Since we can't do a water push out with the hops in there, we do the push out, then add the hops while purging with CO2.

The only previous batch of Neologism was named to Craft Beer & Brewing's Top 20 of 2022... that was the only beer we ever entered into a contest of any type!

Neologism 2024 Tasting Notes

Smell - Expressive in the nose with the gin shining. Spruce tips. Barnyard. Hops aren't as "raw" as an IPA, but it is still fresh smelling.

Appearance - Head is great (dense, long lasting). Slightly hazy golden.

Taste - A little of that guava thing from the first batch is starting to come through, awesome. Pleasant acidity, tart, but not harsh. Gin is a little more savory-herbal than previous gin beers: rosemary, spruce, bruised basil. A touch of oaky-vanillin as it warms.

Mouthfeel - Light astringency, firm carbonation. Light body.

Drinkability - I think this one will continue to improve as the edges soften and the hops integrate more. Still wish we could get more of those McClintock Reserva barrels, but even the second use one really helped this one!

Changes for Next Time - On point! Not this beer… but would still love to do a Tangerine-Gin and/or a Guava Gin at some point.

Risk: Honeymoon SZN

We try a lot of different things that "sound like a good idea." It would certainly be easier and more reliable to pick a slate of brands to make every year. We do rebrew/blend the same beers occasionally, but we don't have a firm schedule and we always try to leave room for inspiration based on what barrels, ingredients, and flavors we have available.

For Honeymoon SZN we started with a collab we brewed at Olde Mother Brewing (Frederick). Wedding SZN was a rice ale with Nelson Sauvin, elderflowers, and Phantasm (along with a natural thiol-releasing yeast strain). We racked it to white wine barrels and let the resident culture work. I sourced muscadine/scuppernong grapes (indigenous) through a local farmstand that has a relationship with a grower in South Carolina. I knew it was a good idea from the aroma of my car on the way back - halfway between Nelson Sauvin and Strawberry candy!

Honeymoon SZN Tasting Notes

Smell - Muscadine really comes through. Lots of white grape juice. Some toasty-funk, but not a primary aroma when cold. Bridges the gap between the Nelson and Brett.

Appearance - Clear. Very pale yellow. Good thick white head that doesn’t last long.

Taste - Light acidity, even less than Life is Ridiculous. Good fruit character, unique, fresh. A touch of funky smoke in the finish I haven’t noticed before. No elderflower.

Mouthfeel - Bright, light, spritzy.

Drinkability - Good, could use a touch more acid, but it is very drinkable as is.

Changes for Next Time - Not sure muscadine is a star… would be fun with a light dry hop. Maybe with another fruit, stone fruit?

Time: Opulence 2024

We age our beers for a long time. Years ago I visited an established brewery that had just added a large barrel facility for sour beers. The brewer running it mentioned he had to meet a monthly production quota for packaged product. Just seems impossible for that to produce fantastic beer. Sometimes we go a month without bottling anything because the beer isn't ready yet... sometimes we are doing back-to-back runs because we don't want something to sit any longer! Opulence 2024 was supposed to be Opulence 2023, but the beer just wasn't ready for the cherries after 8 months in the barrel... but it was at 20 months! We had some leftover high-acidity beer from the previous batch of Opulence kegged off that we blended in with the "fresher" beer that was aged in second-use Cherry Brandy barrels.

Opulence 2024 Tasting Notes

Smell - Reminds me of my homebrews (in a good way). Funk (leathery) really comes through along with cherry and almond. Cherry is really fun, lots of cherry pie, vanilla, and depth. Nothing weird from the cherry brandy barrels considering the previous use was Imperial Stout.

Appearance - I wish the clarity was a little better, but the color is a pleasant amber-orange. Great off-white head.

Taste - Mild acidity, could be a little higher. Detectable bitterness (maybe a hair high). Good cherry flavor, sour cherry pie, vibrant.

Mouthfeel - Light astringency, which is disruptive to the smoothness. Firm carbonation, medium-thin body.

Drinkability - It’s solid. I like the lower acidity compared to past batches, but the bitterness gets in the way.

Changes for Next Time - I wonder if aged hops rather than fresh in the whirlpool would work without providing any weird aromatics? I really like what the Saaz in the whirlpool did for the aroma and balance (lower acidity), but the bitterness clashes with the acidity in flavor… despite being “only” 19 IBUs. Maybe better to go with some alpha acid extract in the tank?

Equipment: Stained 2024

One thing that has worked out well for us is having smaller equipment. Rather than be forced to do big blends, we have equipment that is sized for flexibility. For example, with Stained we age it on wine grapes and raspberries separately. I'm sensitive to the "seedy" flavor that comes from long contact time with raspberries... but I also enjoy the deeper flavors of extended skin contact on grapes. So for this batch we kegged off the raspberry half after two weeks, while the Merlot grapes continued aging for another month until we liked the flavor. This plays into having the time to taste and adjust the production schedule.

Stained 2024 Tasting Notes

Smell - Berries, especially raspberries… go figure. Certainly reads Flemish Red, Rodenbach etc. rather than Lambic thanks to no big funk/rubber.

Appearance - Bright red, thin off-white head drops quickly. Good clarity, but not brilliant. Very attractive.

Taste - Raspberry popsicle, very bright. Suggestion of sweetness from the fruit and malt. THP has cleaned up. Jammy, not overtly malty, but it fills in the fruit. Firm acidity, no harshness. Wine is subdued, but layers complexity and roundness compared to straight raspberries. Clean, not much funk although there is some earthiness. Oak is subdued thanks to third-use barrels.

Mouthfeel - Medium-light, firm carbonation. Not thin or watery, helps support the fruit.

Drinkability - Good, plenty of acid for my tastes, delicious fruit. Could be a little more interesting microbially, but it works in the Flemish tradition.

Changes for Next Time - Could shift more towards the Merlot? Surprised how much acidity it picked up despite the alpha acid extract in the tote.

Out of State Shipping Club

If you are interested in tasting these beers, please sign-up by 10/28! You'll be charged $146 to your card on file and expect to receive your beer the first week of November! Available in: WA, CA, OR, NM, NV, CO, MN, NY, DC, CT, NE, MA, FL, PA, NH, NJ, ID, TX, KS, IN, WI, MO, IA, IL, MI, ND, VA, RI, NC, and SC.

Includes one 500 mL bottle each:

Gindicators 2024: Gin-barrel-aged pale sour with Peaches, Nectarines, and Apricots

Flemish Gothic: 3-year Blend of Wine Barrel Aged Sour Reds

Opulence 2024: Sour Red with Fresh and Dried Sour Cherries aged in Cherry Brandy and Bourbon Barrels

Neologism 2024: Gin-barrel-aged and Mosaic Cryo Dry Hopped

Stained 2024: Wine-barrel-aged with Raspberries and Merlot Grapes

Honeymoon SZN: Wine-barrel-aged with Phantasm and Muscadine/Scuppernong Grapes

The 10 finalists have been chosen by a public vote and will now be assessed by a panel of judges before the winner is announced on 13 September.

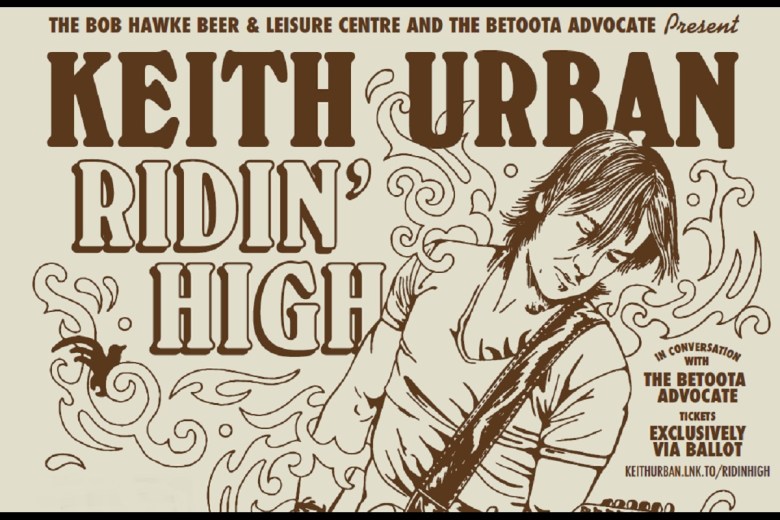

The 10 finalists have been chosen by a public vote and will now be assessed by a panel of judges before the winner is announced on 13 September.  To celebrate the release of his new album Keith Urban is having a night of music and conversation in Marrickville in September.

To celebrate the release of his new album Keith Urban is having a night of music and conversation in Marrickville in September.  Australian Beer Co’s Emma Walton shares lessons and highlights from 20 years of brewing experience across the UK and Australia.

Australian Beer Co’s Emma Walton shares lessons and highlights from 20 years of brewing experience across the UK and Australia.  White Bay Brewery’s Extra Pale Lager is a unique style that stands out from the crowd of craft beer as being something different. It is a style that isn’t yet very common in the beer market and we believe there is demand for it.

White Bay Brewery’s Extra Pale Lager is a unique style that stands out from the crowd of craft beer as being something different. It is a style that isn’t yet very common in the beer market and we believe there is demand for it. If the only things certain in life are death and taxes, then the only things certain in craft beer are inspectors and taxes. For brewers looking to release a new label, that means working with the once-dreaded Taxman.

The post Beer Label Bottlenecks appeared first on CraftBeer.com.

While I love the pure expression of malt, water, hops, microbes, barrel, and time... fruit can make a fantastic addition to a barrel-aged sour. From a "sales" standpoint it is also easier to explain the difference between beers with fruit, than those with subtle differences in grain bill or microbes. Most people know they like cherries, plums, and raspberries... they may not know they enjoy horse blanket, minerality, or rubbery notes.

This is the third in a series of posts updating my thoughts from American Sour Beers ten years ago. The two beers featured below (Jammiest Bit and Fruit of Many Uses) were both part of the first shipment of the Sapwood Cellars Out of State Shipping Club. Memberships for that shipment are closed, but you can still sign-up now for the next shipment fall 2024 ($146/shipment including shipping). Bottles of both are still available at the tasting room!

I would almost always rather use fresh in-season local fruit over a puree, juice, freeze-dried, concentrate, and especially natural extract. Local produce tastes unique, meaning a beer that doesn't taste the same as one brewed on the other side of the country or by a larger brewery. You'll get a more complex character from having beer in contact with the stems, skins, pits etc. Working with farms, orchards, and vineyards "fits" the narrative of an artisanal product... making it look good on social media too! Not to mention our fruiting tanks (without conical and glycol jackets) work best with whole fruit rather than purees.

Talking directly to farms and orchards at farmer's markets is a great place to start. Tasting things, chatting about what sort of capacity (and excess) they might have. Sometimes you can get a good deal on seconds... but for me these often aren't worth it since it can take a lot of time and effort to sort them (going rotten before they are all ripe) and cut-out mold etc.

We've used IQF (Individual Quick Frozen) fruits several times with great results. For smaller batches I've just gone to supermarkets, found a product I like the flavor of... and bought out a couple locations. Online specialty purveyors like Northwest Wild Foods have weird things you might not find locally, like honeyberries. For lager batches we've ordered from Coloma Frozen Foods, but don't do it regularly as refrigerated shipping is expensive. Recently we've been getting our raspberries from Twin Springs Fruit Farm (which freezes their own). Using high-quality frozen fruit is something great lambic breweries do, and it allows to extend the fruiting season so you don't have to have enough tanks for all of your fruit beer at once!

That said, not all fruits are available locally. You can certainly source whole fruits from a good local produce supplier (and we have), but purees have their place too... especially in "smoothie" type sour beers. That said, there is no magic bullet on sourcing them. We've used Oregon Fruit, Greenwood Associates, Kerr/Ingredion, Asceptic Fruit Purees, Hop Havoc, Boiron, FruitGuild, and Araza. None of them are "always good" and none of them are always bad. It's often about preference. For example, Oregon Pineapple is thin, closer to juice, great for an IPA where you'll drop out the solids. Araza Pineapple is much thicker, perfect for a smoothie sour. Both taste great.

Frozen wine grapes are another great option, either juice or must. Again, I love working with local vineyards (Crow Vineyard and Winery has been especially nice to work with), but that isn't always an option! We've had good luck with Grapes for Wine and Wine Grapes Direct.

The only concentrates I've enjoyed are "freeze" concentrates (the wild blueberry and raspberry from Greenwood Associates are great). I've disliked the flavor of all of the standard high-concentration "boiled" concentrates which end up tasting like caramel, and are so thick that they are difficult to mix with beer. Granted, after an early batch with concentrates from Kerr we really haven't tried any more. On the other hand, Kerr's NFC (Not From Concentrate) raspberry juice was terrific, so I suspect the issue was the concentration.

Freeze-dried fruit can be a pretty good option for tropical fruits like mango. I've yet to find a mango puree that didn't taste cooked. The freeze-dried stuff tends to have a brighter "mango popsicle" flavor. It can be pricy, but there is a lot of flavor pound-for-pound. North Bay Trading generally seems to have the best bulk pricing.

We have a chest freezer at the brewery so we can keg fruit when it is ready, but not necessarily have to go onto it immediately. Freezing the fruit also helps break the cell walls allowing better/quicker contact and refermentation. Just make sure to line your freezer with cardboard so the bags don't stick to the interior. That's all we do for berries. Freeze them, let them thaw in the tank, then transfer beer on the next day.

When it comes to larger fruits (e.g., stone fruit like peaches and nectarines) we'll manually quarter them and discard the seeds/pits. In an ideal world we'd selectively process and freeze the fruit on a flow basis as it reached peak ripeness.

I've never had good luck with fermented citrus, so for limes, lemons, oranges, and grapefruit we use the zest. We use a Starfrit Electric Rotato Express. It struggles a bit on really large grapefruits, and we go through a couple a year as they just aren't sturdy enough for a "production" environment.

There is some science that cherry stems have glycosides that Brett can work on to free fruity aromatics... but in practice I find they add a "stemmy" flavor that reminds me of dried leaves. I like the pits though. Obviously nice to find a source that has your preferred processing so you don't have to do it!

However you process the fruit, purge the tank with CO2 thoroughly before transferring beer in. This will help ensure the brightest, freshest, fruit expression possible!

We usually repitch rehydrated (with StartUp/GoFerm) wine yeast along with the fruit to ensure a rapid refermentation, scavenge oxygen, and enhance the fruit character. While our sour beer production area has "light" HVAC, we don't have jackets for our fruiting totes (Flextanks). As a result, we'll change our yeast depending on the seasonal temperature. Usually using more heat-tolerant red wine strains in the summer, and cool-loving whites in the winter.

We also add a small amount (5-7 PPM) of hop extract to prevent additional acidification if the beer is already sour enough for our tastes. See my article on hopping sours for more details.

I've slowly come to be an advocate for relatively short contact time, enough to ferment out the sugars, but not much more. This is especially true of raspberries (which develop a "seedy" flavor from extended contact). I've also heard strawberries as a quick-contact to reduce the phenolic "plastic" flavor they can develop. Although I've also read that can be varietal specific, and others claim freeze-drying can help mitigate.

If I'm aging a beer on raspberries and another fruit that I prefer longer contact, I'll do that separately in two totes. That way we can keg off the raspberry after 10-14 days, while the cherries, wine grapes etc. have a little more contact time (1-2 months). They we blend them together. This could also be accomplished sequentially by racking the beer off of the raspberries and then onto the cherries.

Our Flextanks have stainless steel filters from Utah Biodiesel Supply fitted over the racking arms with stoppers. A false bottom would likely work even better, but with a slow transfer we haven't had many issues with whole/pieces of fruit. The lone one I remember causing havoc with chunks of frozen mango that totally disintegrated.

With all the time and effort of getting the fruit and processing it, we often try to get a second beer out of it. Second use fruit is more subtle, allowing a more "beer-forward" balance. You could likely get similar results from ~25% of the fruiting rate, but second use fruit is easier (and free)!

We'll often just push in a single keg of sour beer onto the fruit from a whole batch to "rinse" it. This gets a big fruit character and it's an easy way to make a unique one-off

We'll do a whole new batch onto especially high fruiting rate beers. For example when we did 4 lbs/gal of raspberries in Throwing Hearts with Other Half, we went onto the fruit with a sour red along with vanilla beans to make Galactic Swirl.

For Fruit of Many Uses, we racked the beer sequentially into each tote after a previous beer. Getting Chardonnay grapes (from Field Learning, our Bissell Brothers collab) before going into barrel, followed by raspberries, then cherries (both from Jammiest Bit), and white nectarines (Polite Company).

We haven't tried it, but I know some brewers who will knock-out fresh wort onto spent fruit as a way to get fruit flavor along with a strong house culture.

No matter your technique, be extra mindful of limiting oxygen exposure as you won't have refermentation to scavenge oxygen.

Barrel #71 Golden Strong #3 (Pils, 2-row, Chit, Wheat malt, and Flaked Wheat to 1.056 with aged Celia and Lemondrop pellets). Primary fermentation with 58W3 and some microbes from a blend of older barrels that was primarily Yeast Bay Mélange (but also various dregs from Oxbow, Jester King, and Backacre). Then aged 17 months in a second-use Malbec barrel. The culture in the barrel itself was originally derived from a De Garde bottle.

Barrel #36 Marylambic #7 (Weyermann Barke Pilsner, Flaked Wheat, and Chit to 1.044 with .5 lbs/bbl aged East Kent Goldings). Primary fermentation T58. Then aged 13 months in a third-use Pinot Noir barrel. The microbes in the oak were originally from dregs from two Floodlands bottles.

Racked into two totes one with 150 lbs Twin Springs Raspberries and the other with 150 Baugher's Orchard Sour Cherries. Both frozen and thawed. Each received 10 g of HopSteiner Alpha Extract, and fresh 71B for refermentation.

Smell - Mix of fresh berries, raspberries more than cherries. Not a hugely complex funky or "Brett-forward" beer, but there is a little lemon and hay Barrel character is hidden behind the fruit as well.

Appearance - Crystal clear, brilliant red-purple. Light-pink head fizzles quickly, but stays as a thin covering.

Taste - Cherries come through more on the palate. Good fruit intensity, still really fresh/vibrant. Firm acidity, slight sharpness from the malic acid of the cherries? Again not an especially complex or funky beer, but it’s a showcase for good fruit. The Baugher's cherries without stems seems to have been a good choice. A bit sweet which lends a more Flemish Red lean rather than Lambic or Saison.

Mouthfeel - Medium-high carbonation. Medium-light body.

Drinkability - It grows on me as I drink it and my palate gets used to the acidity. Good blend of fruit, bright flavor, I just wish the base beer was a little more interesting.

Changes for Next Time - Wouldn’t mind depitted cherries to make sure we are getting good extraction.

Base Beer: Belgian Pale #3

78% Murphy & Rude Virginia Pilsner

18% Murphy & Rude Wheat Malt

4% Murphy & Rude Vienna Malt

OG 1.047

.5 lbs/bbl 5-year-old Australian Summer Hop Pellets

Primary Yeast Lalvin 71-B

Microbes from Chardonnay Grape tote (originally a Bissell Brothers house souring culture they sent for the collab).

Then aged in a third-use Cabernet Sauvignon (microbes originally from Modern Times House of Sand) and Barrel #41 fourth-use merlot barrel for 11 months (microbes in barrel included East Coast Yeast Senne Valley, Bokkereyder dregs, Mad Fermentationist Saison, Casey, and Afterthought dregs)

Racked sequentially onto 150 lbs Twin Springs Raspberries, 150 Baugher's Orchard Sour Cherries, and 250 Twin Springs White Jade Nectarines.

Smell - The berry leads, more cherry than raspberry. Earthy hay, candied fruit salad. The nectarines and grapes don’t shine in the aroma, but they help to send it in a direction that isn’t one-note “berry.” Almost apricot brandy as it warms. I don’t taste anything off from the pits, seeds etc.

Appearance - Carbonation seems a little low. A hard pour results in only a two-finger white head. A few bubbles rising through the pale body. Good clarity.

Taste - Pleasantly tart lemony acidity, without being harsh. The nectarine comes through more distinctly on the palate. Finish is berry again, but light, bright, and juicy finish. Non bitterness.

Mouthfeel - Medium carbonation, could be spritzier. Smooth, no astringency. Light body, without being thin.

Drinkability - Really complex with the different fruit notes coming in and out of awareness.

Changes for Next Time - The Chardonnay is mostly lost, would be a better feature in a plain beer or maybe light dry hopping.

A new wave of Asian American brewers is putting their heritage at the heart of their craft.

The post Redefining Craft Beer: Asian Americans Brewing Up Heritage appeared first on CraftBeer.com.

This is the second in a series of posts each covering an aspect of brewing mixed-fermentation barrel-aged beers where my opinions have changed significantly since I wrote American Sour Beers 10 years ago. Each post will focus on our process, recipe, and results for one of the beers in the Sapwood Cellars Shipping Club (includes 6 bottles, for $146, cancel anytime) - sign-ups for the first box close May 5th! This post covers blending through the lens of Growth Rings 2023 (our blend of 1-, 2-, and 3-year barrel-aged sours). If you are closer to the brewery, May 10th and 11th I'll be doing a talk and vintage sour tasting including pours of Growth Rings 2021 and 2023!

As a homebrewer, my experience with blending was limited to a handful of batches. Over the last six years I've had a hand in blending more than 70 batches of barrel-aged sour beer. So, I thought it would be valuable to give my thoughts on the process, what I've learned to do, and not to do.

You can't blend great beer if you don't have options. Creating variety starts on brew day and continues through fermentation and aging.

Malt Bills - More so for darker sours, it's good to have options for beers that have different flavors to pull from. Even for pale beers, having different grains (wheat, oats, rye, spelt, light caramel malt etc.), and starting gravities can be valuable for creating range.

Hopping Rates - As I discussed in my previous post, hopping rate plays a large role in acidity and "funky" aromatics. Bitterness itself can be a valuable flavor in a blend, it's a flavor present in most lambics, and too often missing from American sours.

Acidity - Having "Brett only" barrels is a good way to ensure you have beer available that won't be too acidic. When a barrel starts getting too sour, we'll often keg it so it is available for blending at a low level for beers that aren't sour enough.

Barrels - A blend of "new" and well-used barrels. Early on all of our barrels were first-use (to us). As a result many of our early releases were too woody, giving "lumber aisle" vibes. Most sour beers are light and delicate and too much oak can overwhelm. At the same time, it's good to retire barrels that aren't producing spectacular beer allowing you to bring in new characterful barrels (we currently have fresh gin, Madeira, PX Sherry etc. aging). If I was starting a new barrel program, I'd soak half of the barrels slated for pale beers with multiple changes of hot water to leach out oak flavor and tannins before filling.

Microbes - It is easiest if you have the same culture in all of the beers/barrels. In that case you don't have to worry about additional attenuation after packaging. For me, it's more valuable to have a variety of microbes for different acid levels and Brett profiles for more dynamic flavor options. As time has gone on we've split the difference, pumping in some of a favorite barrel to a fresh batch, but then going into various barrels with their own cultures. We'll also pitch additional microbes if a barrel isn't headed in a good direction at 6-12 months.

Ages - It can be helpful to have the same/similar beers of various ages so you can balance flavors. We've gotten better at judging which barrels just need more time, and which are headed in a bad direction and need to be dumped. That said, I don't have as much time to taste/monitor the barrels as I should and I still "miss" some good barrels leaving them in too long until they taste oxidized or off.

Think about the goals before you start. What is the concept? What other ingredients are you adding after blending? What is the target volume? Sometimes it is good to just taste barrels for inspiration, but that can be overwhelming when you have dozens of barrels to select from. I try to set a general schedule before the year starts. It keeps me on track for seasonal ingredients, sourcing barrels for finishing, and utilizing our staff/tank time rather than bunching up releases. I tend to earmark barrels as "potential" candidates for a blend, ideally twice as many barrels as a blend would require.

From there, I go to our barrel-spreadsheet (more info). I filter for beers with enough age, appropriate bases, removing barrels that are already earmarked for other projects. Lots of releases overlap, say I fill five barrels with sour red and hope to get a two-barrel blend plain and a two-barrel blend with fruit. Hopefully I have an "orphan" barrel that was passed over from last year or another similar base that didn't fit in its blend available for variety. Then I start pulling nails and tasting to gauge my options. I note barrels that need more time and those that are running out of time. Hopefully that narrows down my choices to five barrels at most for a two or three barrel blend.

Then I pull larger samples of those barrels so I have enough beer for a few blends without having to go back and pull more. When possible, I try to create full-barrel blends, although we occasionally keg-off partial barrels for future blending stock. In the same way if a blend is missing a little something, I'll take a look through our kegs and see if there is an option that satisfies the need.

I usually break down my options by acidity. If two barrels are a bit too acidic and two are not acidic enough, I'll try blending my favorite from each camp together to see where that gets me. Then swap in the other if there is something that doesn't work. Once I get a solid blend, I might go hunting for a little something extra. For example we were just blending a sour red, and ended up with a little 3+ year-aged Vin de Cereale (strong sour red) as a low-percentage malt-booster bringing perceived sweetness and more oak.

In terms of the practicalities of blending, I usually use volume. Weight works, but I tend not to worry about extreme precision because the volume in each barrel can differ by 5-10% anyway. For each blend I start with an empty cup to avoid issues with tracking when you take a sip, dose in more and then don't really know the ratio.

Finally, I write down the winning blend. When possible, I come back and taste the blend on a fresh palate later, ideally with someone who wasn't involved in the initial blend (since that is how the majority of people drinking the beer will approach it).

Blending takes time and practice, but one thing that has been immensely helpful is blending with other people. Some of my favorite collabs are sensory rather than recipe-based. There isn't often much I get out of brewing a collab beer, instead we invite in other brewers to taste through our barrels and help select a blend, brainstorm adjuncts etc. Sam, Tim, and co. from Other Half helped blend Throwing Hearts. Jennings from Pen Druid came in to blend Life is Ridiculous. Mike Thorpe from Afterthought visited last week to blend an upcoming beer with hardy kiwi and New Zealand hops. We've done similar things on the stout side with Mike Saboe from Toppling Goliath and Eric Padilla from More/Open Outcry. Heck it's just great bringing in homebrew friends with good palates to help taste barrels, bounce ideas off... and just give me an excuse to pull samples!

Barrel #16

Beer: Golden Sour (Pils, 2-row, Chit, Wheat Malt, .5 lbs/bbl Aged Hops, 1.056)

Age: 16 Months

Barrel: 5th-fill Pinot Noir American Oak

Culture East Coast Yeast Flemish Ale

Notes: Rubbery funk, medium acid, bright, good

Barrel #19

Beer: Rings of Light (2-row, Chit, Malted Wheat, Unmalted Oats, 40 IBUs in Whirlpool, 1.062)

Age: 8 months

Barrel: 4th-fill Chardonnay American Oak.

Culture: Omega Brett C and Yeast Bay Amalgamation

Notes: Less acidic, funky, bright fruit, rubbery

Barrel #20

Beer: Marylandbic (Pils, Unmalted Wheat, Chit, .5 lbs/bbl 2014 Celeia pellets, 1.045)

Age: 35 months.

Barrel: 2nd-fill Chardonnay American Oak.

Culture: Omega Brett C and Yeast Bay Amalgamation (plus a house culture that was a repitch of a repitch in primary)

Notes: Loamy, a touch stale, bright lactic acid.

Barrel #62

Beer: Belgian Pale (Pilsner, Wheat Malt, Vienna, 15 IBUs Sterling First Wort, 1.048)

Age: 27 months

Barrel: 2nd-fill Cabernet Franc French Oak

Culture: SARA Saison Bernice

Notes: Sprite, tart, but not highly acidic.

Growth Rings is the rare bottle-conditioned sour that we didn't repitch with wine yeast, a good choice if you're looking to harvest bottle dregs!

(My personal notes from a few months ago)

Smell - Citrusy nose, apricot, hay, bright and fresh. Missing that big rubber that is present in most great lambics.

Appearance - Pale gold, clear, lots of bubbles, thick head, good retention. Great lacing.

Taste - Delicate acidity. Lemon, apricot, just a touch of rubber.

Mouthfeel - Snappy carbonation, medium-light body. Lighter bodied than a classic Gueuze.

Drinkability - In terms of drinkability, it’s my favorite recently. Lively, complex… but it isn't as gueuze-y.

Changes for Next Time - It has sort of a barrel-aged saison quality more than gueuze. Maybe that fresher whirlpool hop character from Rings of Light… that said I really like the result.

The longer I brew mixed-fermentation beers, the more I appreciate just how important the hopping rate is. Controlling lactic acid production by inhibiting lactobacillus is hops' most well-appreciated function in sour beers. Hop compounds become more effective at inhibiting Lactobacillus as the pH drops, creating a natural "limit" on their lactic acid production. What it took me a long time to appreciate was how much hop compounds (beyond IBUs) lead to a greater expression of what I think of as classic Brett "funk."

When Scott and I began the mixed-fermentation program in 2018-2019, generally our issue was beers not souring enough. I started pulling levers (lower hopping rates, higher mash temps, less attenuative primary strains etc.) By 2020-2021, we were having excessive acid production... Most non-fruited beers were dropping to a firmly-acidic 3.1-3.3 pH, while fruited beers were often difficult to drink in quantity at 3.0-3.1 pH with some dipping to "obnoxiously acidic" high-2s.

Fruit contributes simple sugars, which Lactobacillus love, and at the same time dilute the hop compounds in the beer. This can cause a precipitous pH drop. With so much beer already in barrels, my first maneuver was to begin dosing alpha acids into the beer along with fruit when there was already enough acid. We started with reduced iso-alpha-acids (e.g. tetralone/hexalone), but have moved onto Hopsteiner Alpha Extract 20% since it doesn't add perceived bitterness. About .1-.2 g per gallon stops acid production for our bacteria. These products don't significantly change the flavor or add additional aromatic complexity. As a side benefit, they enhance head retention. A small dry hop at this stage would be another option if you wanted stop acidification and add hop aromatics.

At this point we started upping the aged hop rate, or aiming for higher IBU targets when using fresh hops (~15-20 IBUs). At the same time (~2021) Scott and Ken (our head brewer) wanted to try barrel-aging more aromatically hoppy beers... I was resistant. I love hoppy-sour beers, I did a whole talk about them at the 2016 National Homebrewers Conference. Generally my approach had been to make sure the hops go into the beer as close to serving as possible (e.g., dry hop a barrel-aged sour after aging, brew a quick-turn hoppy Brett saison, add a whirlpool addition after kettle souring). I'd tasted too many barrel-soured IPAs and pale ales from great breweries that smelled like "old hoppy beer." That said, Ken and Scott convinced me! At our scale it is a relatively low risk to divert a few barrels of pale ale to see what happens.

We're already "aggressive" with our measures against oxygen pick-up (purging barrels with carbon dioxide before filling, purging the barrel-tool between each fill, purging the bottles before filling etc.), but when we fill barrels with pale ale wort we pull out all the tricks. Most importantly, we selected barrels that could be refilled without rinsing, leaving several gallons of "house culture" at the bottom of each. Our goal was to start the secondary fermentation as quickly as possible to protect the delicate hop compounds. I was amazed how good the resulting beer tasted!

What has really intrigued me is that the hoppier bases have almost universally produced finished beers I'd describe as more Brett-forward (earthy, funky, fruity, horse blanket). What I don't know is why! In American Sour Beers I cited research that Brett can free glycosides in hops, so that could explain the fruity. Maybe hops are just inhibiting Lactobacillus, giving the Brett a healthier environment (in lambics Brett tends to thrive before Pediococcus dramatically lowers the pH). Maybe I'm just being fooled and higher hopping rates (aged or fresh) are adding key compounds that I associate with the "funk" in a Cantillon, Orval (and many of my favorite American mixed-ferms)! These days our typical hopping rate is .5 lbs/bbl of aged hops at the start of the boil, and .5 lbs/bbl or fresh low alpha-acid hops in the whirlpool.

Barrels of Rings is one of the bottles included with the first shipment of the Sapwood Cellars Shipping Club. It started as Rings of Light, brewed summer 2022, racked into barrels after primary fermentation, but before dry hopping. After 10 months of aging, we transfer directly from the two wine barrels into our blending tank (purged with 5.5 pounds of our selected Citra Cryo already in there). We agitated/roused and allowed to settle for a couple days, dropping the hops. Then we primed with sugar and rehydrated wine yeast (as we do for most of our barrel-aged sours) and partially carbonated the beer. As with the barrel fill, we're relying on CO2 purging of the bottles and the rapid refermentation to scavenge oxygen and preserve hop aromatics.

Recipe: Barrels of Rings

OG: 1.063

65% Briess Brewer's 2-row

14% Great Western Malted White Wheat

13% Grain Millers Flaked Oats

8% Best Chit Malt

IBUs: 40

.5 lbs/bbl Meridian @ Whirlpool (212F)

1 lb/bbl New York Cascade @ Whirlpool (180F)

Bravo Salvo Hop Extract @ Whirlpool (180F)

Fermentation with Omega Cosmic Punch (the barrel sheet below is incorrect)

FG (Primary) 1.022

Brewed 8/5/22. Barrels filled 8/11/22

Barrel #6: Fifth-fill Chambourcin red wine barrel that previously held our original barrel-aged pale ale, Measure Twice. That barrel was started with dregs from our collab with Free Will (Erma Extra), but along the way it was filled with bases that had dregs in primary from various American saisons (Casey and Holy Mountain).

Barrel #125: Second-fill Chardonnay white wine barrel that previously held a cider fermented with the Bootleg Biology Biology Mad Fermentationist Saison (plus we added the dregs from a stellar bottle of Barrique Wet Hop Reserve after filling).

6/21/23 116 gallons of beer from the two barrels transferred onto 5.5 pounds of 2022 Citra Cryo. 1.5 oz/gallon.

Carbonated to 2.05 vol, reyeasted with Premier Cuvee (rehydrated on a stir-plate with StartUp Nutrient), primed with enough glucose to add 1.1 vol of CO2 (~3.1 vol total in bottle).

Final pH: 3.65

Final Gravity 1.009

7.1% ABV.

Tasting Notes: Barrels of Rings

(My personal notes from a few months ago)

Smell - Nice blend of citrus (orange) and earthy-Bretty-funk. Still really fresh, no oxidative or old-hop aromatics. Really varied nose with a little pine sap, hay, and melon. Another hoppy base that got funkier than most of our bases.

Appearance - Big dense white head, good retention. Light haze, very pale yellow. Attractive.

Taste - Light lemony tartness, but not sour-sour. Very saison-y. Some bitterness, but it doesn’t clash with the light bitterness.

Mouthfeel - A touch of astringency. Great sptrizy carbonation. Medium-light body.

Drinkability - Really nice. The bitterness does give it a different impression than a classic low-bitterness sour base. More saison-like.

Changes for Next Time - Really good, not much to change on this one. Gin barrels would be fun.

When visiting Epochal Barrel Fermented Ales in Scotland last year I was blown-away by how by how good (owner/brewer) Gareth Young's wild ales were aged on whole hops in the barrels for the entire secondary fermentation. I really enjoyed the first beer we did with it, Violet You're Turning Violet (Mosaic in the barrel, finished with a blend of wild and cultivated blueberries). It seems like a good option especially if you want variety in the hop intensity of a base, e.g., start with a more moderate hopped base and add hops to some barrels for blending options.

Breweries from across the country are celebrating the annual Australian hop harvest with hop festivals and fresh brews.

Breweries from across the country are celebrating the annual Australian hop harvest with hop festivals and fresh brews.  The Australian trivia company is celebrating its 20th anniversary by partnering with craft brewers for a series of uniquely-flavoured beers.

The Australian trivia company is celebrating its 20th anniversary by partnering with craft brewers for a series of uniquely-flavoured beers. (Paso Robles, CA) – Firestone Walker today unveiled its first of three seasonal offerings slated for 2024—the all-new Firestone XPA, a next-generation extra pale ale brewed with Southern Hemisphere hops […]

The post Firestone XPA – Details On Firestone Walker’s Newest Seasonal appeared first on The Full Pint - Craft Beer News.

Smoothie sours are attracting a whole new audience of beer drinkers that otherwise would not make their way into a brewery.

The post Cheesecake and Ice Cream and Blueberry, Oh My: The Allure of Smoothie Sours appeared first on CraftBeer.com.

(BALTIMORE, MARYLAND) – The brewing process employed to create Guilford Hall Brewery’s new Czech Amber Lager dates back to the early 1700s. The extra steps required in a triple-decoction brewing […]

The post Guilford Hall Brewery Debuts New Czech Amber Lager appeared first on The Full Pint - Craft Beer News.

The United States is home to more than 18,000 islands, and for travel lovers, many are worth adding to a list of must-see destinations. Luckily for craft beer enthusiasts, there are breweries located on several of these islands.

The post These 19 Breweries Are on U.S. Islands appeared first on CraftBeer.com.

Quality matters at any size brewery, and the team behind beer quality is what matters most since data doesn’t analyze itself.

The post The People Behind Beer Quality appeared first on CraftBeer.com.

Pairing produce with beer — with delicious results. A look at the glorious interplay between farmers market fare and craft beer.

The post A Great Beer for Greens appeared first on CraftBeer.com.

Meanwhile, Tooheys have brought back the 6.5% Extra Dry Platinum and Coopers' new lager officially launches.

The post Gage and Capital add “better for you” drinks appeared first on Beer & Brewer.

Their Japanese Style Lager and Extra Special Bitter won Champion Packaged and Champion Draught respectively.

The post 4 Pines beers crowned Sydney Royal champions appeared first on Beer & Brewer.

When it comes to brewing delicious beer, there are few aspects more important than the yeast. A healthy fermentation allows the malt, hops, and adjuncts to shine. Pitching the right amount of healthy cells helps ensure that the finished beer has the intended alcohol, expected residual sweetness, and appropriate yeast character.

Over the last four years at Sapwood Cellars we've slowly improved our yeast handling. We've noticed improved fermentation consistency, and better tasting beers. Most of our process is excessive for a homebrewer, but it might give you some ideas!

Harvesting Yeast

We harvest yeast from moderate gravity beers when possible as these cells are less stressed and healthier as a result. Our general rhythm is to brew a pale ale with a fresh pitch, and harvest from that tank for an IPA and DIPA the following week. Once the pale ale fermentation is complete (repeated gravity readings, and no diacetyl or acetaldehyde sensory) we can and soft-crash to 56-58F (13-14C). Cold and dissolved CO2 encourage the yeast to settle out. Specific temperature and time are strain and tank dependent, but that works for most of the English-leaning strains we use (Boddington's, Conan, Whitbread, and the Thiolized-variants).

Once the beer has been cold for 24 hours, we attach a 1/2 bbl brink to the bottom of the tank and pasteurize through the line and brink with 180F (82C) water from our on-demand. 25 minutes hot ensures there aren't any stray microbes that will be passed onto the subsequent batches. After pushing out the water with CO2 pressure we spray the brink with cold water then pressurize it and the tank to ~10 PSI.

We then dump about a gallon (4L) from the T until the yeast looks good (creamy, off-white) and then begin collecting into the brink. You don't need to dump a large volume of yeast. By keeping steady pressure on the tank and slowly releasing pressure on the brink through the valve at the top we ensure that the yeast won't come out of the cone too quickly (which could punch through pulling in more beer than yeast) and won't foam up in the brink. It takes 10-15 minutes to fill the brink. Usually we are able to collect 110-130 lbs (50-60 kg) before yeast starts coming out the top of the brink.

We collect yeast before dry hopping to avoid having hops mixed in with the yeast. We also prefer the "less rough" flavor we achieve by dry hopping cold. If you dry hop early-mid fermentation and want to harvest, drop as much of the hops out as you can before crashing and harvesting.

Yeast Storage

Whenever possible we pitch within 72 hours of harvest. Larger yeast cultures generate more heat and thus tend to lose viability more rapidly. Store the yeast as cold as possible, which for us is ~36F (2C) in our walk-in. Ideally that would be closer to 32F (0C) to further slow its metabolism. Shake twice a day to dissipate hot-spots and vent down the pressure to knock-out CO2. If storing the yeast for more than a few days, attach a blow-off line to prevent pressure from building.

There are studies about various additives for maintaining high yeast viability. We've added phosphate buffer to prevent a drastic pH drop. It's difficult to tell from a single data point, but viability dropped from 95% to 89% after a week of storage. We've seen closer to 10% reductions the handful of times we've stored yeast that long previously.

We generally won't harvest and repitch beyond three generations (although recently we went to five). That's because with our limited number of tanks, variety of yeast strains, and canning schedule we'd eventually have to hold onto yeast for a couple of weeks before pitching or harvest from a strong beer.

Determining Cell Count and Viability

There are plenty of successful brewers who pitch a standard weight by barrel/gravity, but knowing how many live cells you actually have is a great way to improve consistency. It's especially valuable if you use a variety of strains or want to bring in a new strain. Our harvests of the same strain can vary by as much as three times in terms of live cells per g of slurry (~.5-1.5 billion cells). The cost of all of the equipment required is ~$500, less than a single commercial 10 bbl yeast pitch from some labs.

Start by shaking the brink to homogenize the culture. Then run a cup of yeast out, dump it (to avoid counting the cells packed around the port) and then pull a sample. The next step is to dilute the culture to a "workable" concentration - 1:100 for us. Too many cells packed together makes for a culture that is impossible/laborious to count, while too few raises the chances luck will throw-off the count. For a long time I diluted by volume, performing two sequential 10X dilutions with a micropipette. This had two drawbacks. First getting an accurate volume of yeast slurry is tricky because it is foamy and has small bits of trub that can plug-up the pipette. Second, we pitch by weight, so there was always some estimation when it came to converting the volume to a weight or the extra step of determining the physical density of the slurry by mixing with water in a graduated cylinder on a scale. What we do now is dilute by weight, which gives us cells per gram rather than cells per milliliter.

Our scale is accurate to .2 g, so weighing 1 g of yeast into 99 g of water has a ~20% margin of error. As a result I do 490 g of water with 5 g of the yeast slurry. This reduces the maximum margin of error to ~4%. After pouring the diluted culture back and forth to mix, I take 9.9 mL of the diluted culture with the micropipette and add .1 mL of a stock dye solution of Erythrosin B and phosphate buffer (1 g in 50mL of buffer). This results in a total dilution of 100X. You could go even further, a 10X dilution by weight (50 g yeast with 450 g of water) followed by a 10X dilution by volume (1 mL of the diluted culture with 8.9 mL water and .1 g of dye). Live cells are able to expel the Erythrosin B so they won't be stained, meaning any red yeast cells are dead. You can use a variety of other stains, but Erythrosin B is a food coloring and much safer to handle than methylene blue or trypan blue. Here's a post from Escarpmant Labs on using it inspired by my Tweet (which was in turn inspired by this).

Luckily the Boddingtons-type strain we use for most of our batches isn't "excessively" flocculent. When we fermented a run with Whitbread we ran into issues with the cells being too clumpy to count. Luckily BrewKaiser has a whole post on additions you can add to help. Phosphoric acid worked OK, but a local brewer suggested disodium EDTA, which I plan to buy before we do another run with a similar strain.

Next, place a couple drops on the diluted culture a hemocytometer, apply the slide cover, and stick it under a microscope (we have an Omax). Count the live and dead cells in five squares (each made up of 25 small squares) - four corners, and center. This provides a large enough sample size to avoid undue randomness. A small tally counter helps keep track. The standard rule is to count cells touching the left and top lines, but not the right or bottom. Count connected cells as two only if the daughter cell is more than half the size of the mother. Then I plug the totals into Inland Island's Yeast Cell Count Calculator. Usually our harvests are 80-90% viable off a fresh pitch, and they tend to go up from there on subsequent generations (90-95%). If your viability isn't great it could either be that the yeast isn't getting enough nutrients/oxygen, your initial pitching rate was too high or low, or that you are waiting too long to harvest.

There are automated solutions for yeast counting, but with some practice the whole processes will take less than 10 minutes.

Pitching YeastTo pitch, we attach the brink to a T inline during knock-out. With the brink on a scale we use CO2 to slowly push in the desired weight of yeast (calculated based on the cell count, wort gravity, and volume). We pitch during knock-out so the yeast mixes with the aerated wort as it goes into the fermentor. White Labs advocates using a pump to pitch their fresh yeast inline to achieve better mixing with the wort. Best practice is to do another cell count off the tank once knock-out is complete to validate your process (we did it a few times, but now trust our approach).

When we started brewing more double batches to fill our 20 bbl tanks, we were pitching enough cells for 20 bbls along with the first 10 bbls of wort. Our thought process was that the yeast wouldn't do much in the 3-4 hours before the second half of the wort went in. However, we found our fermentations were less reliable, often dragging towards terminal gravity, and the yeast from those batches had much lower viability than expected. Both of these issues improved significantly once we switched to pitching only enough cells for the initial knock-out volume. This allows for more growth and thus a higher proportion of younger yeast cells.

Hopefully this overview of our process is helpful for someone starting a new craft brewery, or looking to take their yeast management to the next level. As with anything in brewing, the more variables you can track and control the more consistency you'll have in your results. Yeast management isn't a "fun" topic, but it is one of the simplest things a brewery can do to increase consistency, improve flavor, and save money!

From brewery hotels to campgrounds, quirky Airbnbs to luxurious resorts, this is your guide to planning a craft beer weekend getaway.

The post AirbnBeers: Breweries with Hotels, Inns, Camping and More appeared first on CraftBeer.com.

(Portland, OR)- Portland’s Ecliptic Brewing and Seattle’s Holy Mountain Brewing are releasing an Extra Juicy Pale Ale this summer. The fourth beer in Ecliptic’s 2022 Cosmic Collaboration Series will ship August 24th in 16-ounce cans and draft. Ecliptic + Holy Mountain Extra Juicy Pale Ale is brewed with Pale and Pilsner malts and dry-hopped with Vista […]

The post Ecliptic Brewing and Holy Mountain Brewing Brew Extra Juicy Pale Ale appeared first on The Full Pint - Craft Beer News.

Dozens of U.S. growers supply breweries with high-quality hops. These hop farms are often family-run, and count their acreage in double-digits vs. thousands.

The post Craft Hop Growing in the U.S. appeared first on CraftBeer.com.

You know the saying: “Give a man a fish, and you feed him for a day. Teach a man to fish, and you feed him for a lifetime.” Well, beer’s always been there for fish, but only recently have chefs around the country sufficiently established the pairings between seafood and suds to make them part […]

The post Salinity & Suds: Pairing Beer with Seafood appeared first on CraftBeer.com.