ales

Festival goers can expect to find 120 festival-exclusive beers and cocktails at GABS, which is now in its 14th year.

Festival goers can expect to find 120 festival-exclusive beers and cocktails at GABS, which is now in its 14th year. The main harvest window for citrus fruits runs from November to March, so why isn’t that period citrus beer season?

The post Citrus Sunshine in the Cold Winter appeared first on CraftBeer.com.

Communal singing groups unite people through casual, joyful experiences blending beer and song, fostering connection and rediscovery in community spaces.

The post Singing For Your Beer: Hops & Hymn appeared first on CraftBeer.com.

From Danny Fullpint, Editor-in-chief: This is a longstanding year-end tradition here at The Full Pint. While the beer industry and beer enthusiasm has changed, one thing stayed the same. Kyle Harrop, of Horus Aged Ales continues to travel the world collaborating on beers and remains a tastemaker, uncovering new and obscure small beer makers in […]

The post Kyle Harrop’s (Horus) Top 10 Beers of 2024 appeared first on The Full Pint - Craft Beer News.

Don't call it a comeback: Detroit's vibrant craft beer scene mirrors the city's own renaissance.

The post Celebrating Detroit’s Craft Beer History appeared first on CraftBeer.com.

The votes have been counted and we are delighted to reveal the finalists for the 2024 Beer & Brewer Awards.

The votes have been counted and we are delighted to reveal the finalists for the 2024 Beer & Brewer Awards.  The 10 finalists have been chosen by a public vote and will now be assessed by a panel of judges before the winner is announced on 13 September.

The 10 finalists have been chosen by a public vote and will now be assessed by a panel of judges before the winner is announced on 13 September.  One of the pioneers of Australia's craft beer scene is hanging up his boots at 'The Lord' after 40 years of brewing.

One of the pioneers of Australia's craft beer scene is hanging up his boots at 'The Lord' after 40 years of brewing.  Belma IPA heroes a unique American hop variety and celebrates the importance of IPAs to the Pirate Life brand.

Belma IPA heroes a unique American hop variety and celebrates the importance of IPAs to the Pirate Life brand.  From Irish stout to hazy pale ales, Beer & Brewer rounds up the best non-alcoholic beers for Dry July.

From Irish stout to hazy pale ales, Beer & Brewer rounds up the best non-alcoholic beers for Dry July.  After a period of review and consultation Lion has made the ‘difficult decision’ to close its Malt Shovel Brewery.

After a period of review and consultation Lion has made the ‘difficult decision’ to close its Malt Shovel Brewery. The longer I brew mixed-fermentation beers, the more I appreciate just how important the hopping rate is. Controlling lactic acid production by inhibiting lactobacillus is hops' most well-appreciated function in sour beers. Hop compounds become more effective at inhibiting Lactobacillus as the pH drops, creating a natural "limit" on their lactic acid production. What it took me a long time to appreciate was how much hop compounds (beyond IBUs) lead to a greater expression of what I think of as classic Brett "funk."

When Scott and I began the mixed-fermentation program in 2018-2019, generally our issue was beers not souring enough. I started pulling levers (lower hopping rates, higher mash temps, less attenuative primary strains etc.) By 2020-2021, we were having excessive acid production... Most non-fruited beers were dropping to a firmly-acidic 3.1-3.3 pH, while fruited beers were often difficult to drink in quantity at 3.0-3.1 pH with some dipping to "obnoxiously acidic" high-2s.

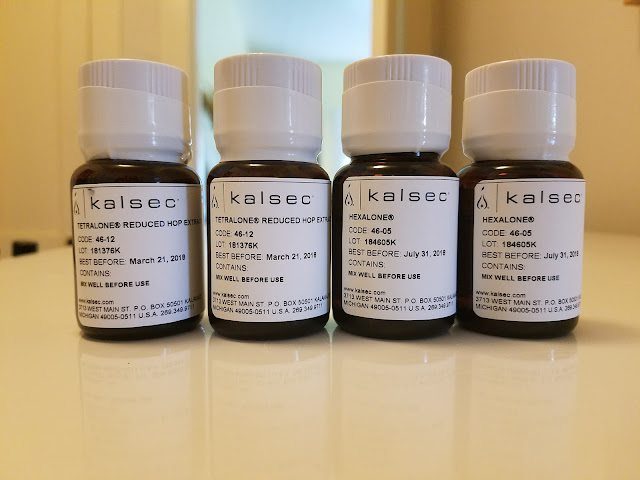

Fruit contributes simple sugars, which Lactobacillus love, and at the same time dilute the hop compounds in the beer. This can cause a precipitous pH drop. With so much beer already in barrels, my first maneuver was to begin dosing alpha acids into the beer along with fruit when there was already enough acid. We started with reduced iso-alpha-acids (e.g. tetralone/hexalone), but have moved onto Hopsteiner Alpha Extract 20% since it doesn't add perceived bitterness. About .1-.2 g per gallon stops acid production for our bacteria. These products don't significantly change the flavor or add additional aromatic complexity. As a side benefit, they enhance head retention. A small dry hop at this stage would be another option if you wanted stop acidification and add hop aromatics.

At this point we started upping the aged hop rate, or aiming for higher IBU targets when using fresh hops (~15-20 IBUs). At the same time (~2021) Scott and Ken (our head brewer) wanted to try barrel-aging more aromatically hoppy beers... I was resistant. I love hoppy-sour beers, I did a whole talk about them at the 2016 National Homebrewers Conference. Generally my approach had been to make sure the hops go into the beer as close to serving as possible (e.g., dry hop a barrel-aged sour after aging, brew a quick-turn hoppy Brett saison, add a whirlpool addition after kettle souring). I'd tasted too many barrel-soured IPAs and pale ales from great breweries that smelled like "old hoppy beer." That said, Ken and Scott convinced me! At our scale it is a relatively low risk to divert a few barrels of pale ale to see what happens.

We're already "aggressive" with our measures against oxygen pick-up (purging barrels with carbon dioxide before filling, purging the barrel-tool between each fill, purging the bottles before filling etc.), but when we fill barrels with pale ale wort we pull out all the tricks. Most importantly, we selected barrels that could be refilled without rinsing, leaving several gallons of "house culture" at the bottom of each. Our goal was to start the secondary fermentation as quickly as possible to protect the delicate hop compounds. I was amazed how good the resulting beer tasted!

What has really intrigued me is that the hoppier bases have almost universally produced finished beers I'd describe as more Brett-forward (earthy, funky, fruity, horse blanket). What I don't know is why! In American Sour Beers I cited research that Brett can free glycosides in hops, so that could explain the fruity. Maybe hops are just inhibiting Lactobacillus, giving the Brett a healthier environment (in lambics Brett tends to thrive before Pediococcus dramatically lowers the pH). Maybe I'm just being fooled and higher hopping rates (aged or fresh) are adding key compounds that I associate with the "funk" in a Cantillon, Orval (and many of my favorite American mixed-ferms)! These days our typical hopping rate is .5 lbs/bbl of aged hops at the start of the boil, and .5 lbs/bbl or fresh low alpha-acid hops in the whirlpool.

Barrels of Rings is one of the bottles included with the first shipment of the Sapwood Cellars Shipping Club. It started as Rings of Light, brewed summer 2022, racked into barrels after primary fermentation, but before dry hopping. After 10 months of aging, we transfer directly from the two wine barrels into our blending tank (purged with 5.5 pounds of our selected Citra Cryo already in there). We agitated/roused and allowed to settle for a couple days, dropping the hops. Then we primed with sugar and rehydrated wine yeast (as we do for most of our barrel-aged sours) and partially carbonated the beer. As with the barrel fill, we're relying on CO2 purging of the bottles and the rapid refermentation to scavenge oxygen and preserve hop aromatics.

Recipe: Barrels of Rings

OG: 1.063

65% Briess Brewer's 2-row

14% Great Western Malted White Wheat

13% Grain Millers Flaked Oats

8% Best Chit Malt

IBUs: 40

.5 lbs/bbl Meridian @ Whirlpool (212F)

1 lb/bbl New York Cascade @ Whirlpool (180F)

Bravo Salvo Hop Extract @ Whirlpool (180F)

Fermentation with Omega Cosmic Punch (the barrel sheet below is incorrect)

FG (Primary) 1.022

Brewed 8/5/22. Barrels filled 8/11/22

Barrel #6: Fifth-fill Chambourcin red wine barrel that previously held our original barrel-aged pale ale, Measure Twice. That barrel was started with dregs from our collab with Free Will (Erma Extra), but along the way it was filled with bases that had dregs in primary from various American saisons (Casey and Holy Mountain).

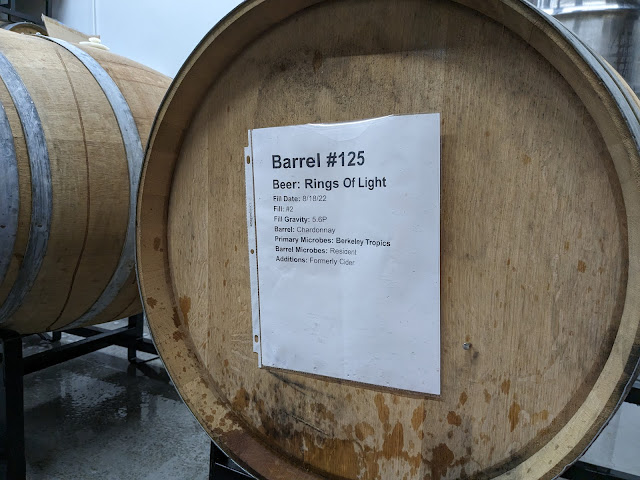

Barrel #125: Second-fill Chardonnay white wine barrel that previously held a cider fermented with the Bootleg Biology Biology Mad Fermentationist Saison (plus we added the dregs from a stellar bottle of Barrique Wet Hop Reserve after filling).

6/21/23 116 gallons of beer from the two barrels transferred onto 5.5 pounds of 2022 Citra Cryo. 1.5 oz/gallon.

Carbonated to 2.05 vol, reyeasted with Premier Cuvee (rehydrated on a stir-plate with StartUp Nutrient), primed with enough glucose to add 1.1 vol of CO2 (~3.1 vol total in bottle).

Final pH: 3.65

Final Gravity 1.009

7.1% ABV.

Tasting Notes: Barrels of Rings

(My personal notes from a few months ago)

Smell - Nice blend of citrus (orange) and earthy-Bretty-funk. Still really fresh, no oxidative or old-hop aromatics. Really varied nose with a little pine sap, hay, and melon. Another hoppy base that got funkier than most of our bases.

Appearance - Big dense white head, good retention. Light haze, very pale yellow. Attractive.

Taste - Light lemony tartness, but not sour-sour. Very saison-y. Some bitterness, but it doesn’t clash with the light bitterness.

Mouthfeel - A touch of astringency. Great sptrizy carbonation. Medium-light body.

Drinkability - Really nice. The bitterness does give it a different impression than a classic low-bitterness sour base. More saison-like.

Changes for Next Time - Really good, not much to change on this one. Gin barrels would be fun.

When visiting Epochal Barrel Fermented Ales in Scotland last year I was blown-away by how by how good (owner/brewer) Gareth Young's wild ales were aged on whole hops in the barrels for the entire secondary fermentation. I really enjoyed the first beer we did with it, Violet You're Turning Violet (Mosaic in the barrel, finished with a blend of wild and cultivated blueberries). It seems like a good option especially if you want variety in the hop intensity of a base, e.g., start with a more moderate hopped base and add hops to some barrels for blending options.

Brandon Hernández combed the desert and laid out a stellar septet of breweries to visit in Las Vegas.

The post Vegas (Beer), Baby! appeared first on CraftBeer.com.

France is famous for its attachment to good food and good alcohol—the French art de vivre. Beer still doesn’t seem to qualify as such. But that might be changing.

The post France Is Not a Beer Country, but It Could Be appeared first on CraftBeer.com.

In addition to music venues, bodacious barbecue, and epic tacos, this booming metropolis is The Lone Star State’s leading locale for incredible craft beer.

The post Three Beer-Filled Days in Austin, Texas appeared first on CraftBeer.com.

Bière de garde is a malty style of beer that is undiscovered to many. Translated to "beer for keeping," the style was traditionally brewed in Northern France and is known for its malt-focused, toasty taste, and slight sweetness.

The post Bière de Garde: ‘A Breath of Fresh Air’ appeared first on CraftBeer.com.

To reach the broadest possible demographic, breweries are embracing kosher certification.

The post Keeping Kosher in Craft Beer appeared first on CraftBeer.com.

This week I examine a group of US hops from the Pacific Northwest. These American hops form the heart of the US Craft Beer revolution and are widely used in American Pale Ale, and the wide array of India Pale Ales (IPAs) that now dominate Craft Beer production in the US. The Pacific Northwest Hops […]

This week I examine a group of US hops from the Pacific Northwest. These American hops form the heart of the US Craft Beer revolution and are widely used in American Pale Ale, and the wide array of India Pale Ales (IPAs) that now dominate Craft Beer production in the US. The Pacific Northwest Hops […] Breweries across the country are using game nights to draw in diverse crowds, welcome new guests, and expand their communities.

The post Bingo! Breweries Score on Game Night appeared first on CraftBeer.com.

This week I welcome back Gordon Strong to discuss lager fermentation, lager yeast flavors, judging beer as well as some trends in craft brewing. Subscribe on iTunes to Audio version or Video version or Spotify or Google Play Download the MP3 File– Right Click and Save As to download this mp3 file. Your browser does […]

This week I welcome back Gordon Strong to discuss lager fermentation, lager yeast flavors, judging beer as well as some trends in craft brewing. Subscribe on iTunes to Audio version or Video version or Spotify or Google Play Download the MP3 File– Right Click and Save As to download this mp3 file. Your browser does […]  Adam Mills joins me this week to discuss the use of Thiol boosting yeast, mash hopping and other techniques to enhance the tropical/fruity flavors in IPAs and New England IPAs. Subscribe on iTunes to Audio version or Video version or Spotify or Google Play Download the MP3 File– Right Click and Save As to download […]

Adam Mills joins me this week to discuss the use of Thiol boosting yeast, mash hopping and other techniques to enhance the tropical/fruity flavors in IPAs and New England IPAs. Subscribe on iTunes to Audio version or Video version or Spotify or Google Play Download the MP3 File– Right Click and Save As to download […]